Stainless steel pipes offer numerous advantages, including exceptional corrosion resistance, which makes them ideal for use in harsh environments. They possess high tensile strength and durability, ensuring long-term performance and reliability. Additionally, stainless steel pipes have a smooth surface that reduces friction and enhances fluid flow. They are also resistant to high temperatures and pressure, making them suitable for a wide range of applications. Furthermore, they are easy to clean and maintain, ensuring high hygiene standards in industries like food and beverage production. Their recyclability also contributes to environmental sustainability.

Galvanized steel is mild steel with a coating of zinc. The zinc protects the steel by providing cathodic protection to the exposed steel, so should the surface be damaged the zinc will corrode in preference to the steel.

Galvanized steel coils offer several key advantages, including excellent corrosion resistance due to their protective zinc coating, which extends their lifespan and reduces maintenance costs. They provide superior durability and strength, making them suitable for demanding applications in construction and manufacturing. These coils are also cost-effective, offering a good balance between performance and price. Their versatility allows for easy fabrication and welding, accommodating various design requirements. Additionally, galvanized steel coils are aesthetically pleasing with a clean, uniform appearance, and they are environmentally friendly as they can be recycled.

Galvanized steel pipes offer several notable advantages, including superior corrosion resistance due to their zinc coating, which extends their lifespan and reduces the need for frequent maintenance. They are durable and strong, capable of withstanding high pressure and harsh environmental conditions. These pipes are cost-effective, providing a long-term solution at a reasonable price. Additionally, they are versatile and can be used in a wide range of applications, from plumbing to structural projects. The zinc coating also enhances their aesthetic appeal, making them suitable for visible installations. Overall, galvanized steel pipes combine durability, reliability, and affordability.

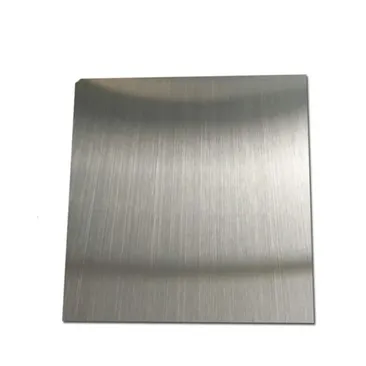

Brushed stainless steel plates offer several key advantages. They have an attractive, modern appearance with a distinctive, satin-like finish that enhances aesthetic appeal. These plates are highly durable and resistant to corrosion, making them suitable for both indoor and outdoor applications. The brushed finish helps to conceal fingerprints and minor scratches, maintaining a clean look with minimal maintenance. Additionally, brushed stainless steel is easy to clean and has hygienic properties, making it ideal for environments requiring high standards of cleanliness, such as kitchens and medical facilities. Their combination of visual appeal, durability, and ease of maintenance makes them a versatile and practical choice for various applications.

Mirror stainless steel plates offer numerous advantages, including an exceptionally high reflectivity that creates a visually striking, mirror-like finish, enhancing the aesthetic appeal of any application. They are highly durable and resistant to corrosion, ensuring long-term performance even in harsh environments. The smooth, polished surface is easy to clean and maintain, making it ideal for applications requiring high standards of hygiene, such as in medical facilities and kitchens. Additionally, the reflective quality of these plates can enhance lighting and create an illusion of larger spaces in architectural and interior design. Their blend of beauty, durability, and practicality makes them a versatile choice for a wide range of decorative and functional applications.

Seamless stainless steel pipes find application across diverse industries due to their exceptional corrosion resistance, high strength, and reliability. They are extensively used in the oil and gas sector for transporting corrosive fluids and gases, in chemical processing plants for handling aggressive chemicals, and in the food and beverage industry for maintaining hygiene standards. Additionally, they serve in structural applications in construction, in automotive and aerospace sectors for critical components, and in power generation plants for conveying high-pressure steam and gases. Their versatility and durability make them indispensable in numerous industrial and commercial applications.

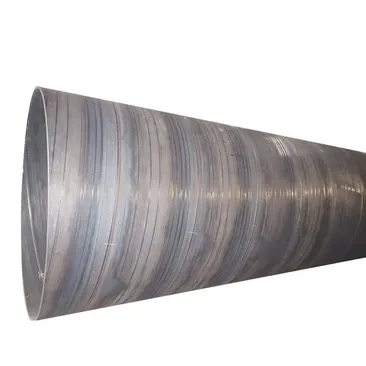

The advantages of welded stainless steel pipes include cost-effectiveness, versatility, and ease of customization. Welded pipes are produced by welding steel strips or plates together, allowing for efficient mass production and lower manufacturing costs compared to seamless pipes. They can be fabricated in various shapes and sizes to suit specific application requirements, offering flexibility in design. Welded stainless steel pipes also exhibit good mechanical properties and can withstand high temperatures and pressures, making them suitable for a wide range of industrial and structural applications. Additionally, welded pipes are readily available in large quantities, providing a reliable and accessible solution for various piping needs.

The advantages of 303 stainless steel plates lie in their exceptional machinability, good corrosion resistance, and versatility. With sulfur addition for improved machinability, these plates are easily shaped, drilled, and cut, making them ideal for intricate parts and components. Their corrosion resistance, particularly in mildly corrosive environments, ensures longevity and reliability in various applications. Additionally, 303 stainless steel plates exhibit good mechanical properties, such as high tensile strength and hardness, further enhancing their suitability for a wide range of industrial and commercial uses.

The A106 carbon steel pipe offers several key advantages, including excellent strength and durability, making it suitable for high-pressure and high-temperature applications. It has outstanding weldability and machinability, facilitating easy fabrication and installation in complex piping systems. Its ability to withstand harsh conditions and maintain structural integrity under extreme temperatures and pressures makes it ideal for critical applications in oil and gas refineries, power plants, and petrochemical plants. Overall, the A106 carbon steel pipe combines strength, reliability, and versatility, ensuring optimal performance in demanding industrial environments.