DX51D galvanized sheet material is a non-ferrous alloy mainly composed of zinc as the matrix and other elements. The main alloy elements are aluminum, copper, magnesium, etc. Zinc alloy has low melting point, good fluidity, easy plastic processing and welding, and is resistant to atmospheric corrosion. According to the manufacturing process, it can be divided into cast zinc alloy and deformed zinc alloy. The commonly used cast zinc alloy is zinc aluminum copper magnesium alloy. Its casting process performance is good, and the cooling rate has little impact on the mechanical properties. It is mainly used to manufacture mechanical parts, toys, decorations, household appliances, etc.

Galvanized coil G550 belongs to high-strength series galvanized sheet, with high requirements for tensile strength and yield strength. Its minimum yield strength is 560Mpa, minimum tensile strength is 650Mpa, and zinc layer thickness is 275g/m2. It has strong corrosion resistance and is mainly used for building structures with high strength requirements, such as Z-shaped steel, C-shaped steel, floor bearing plate, etc.

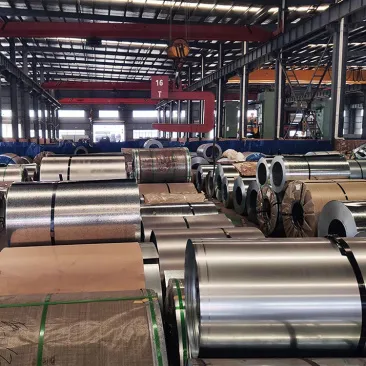

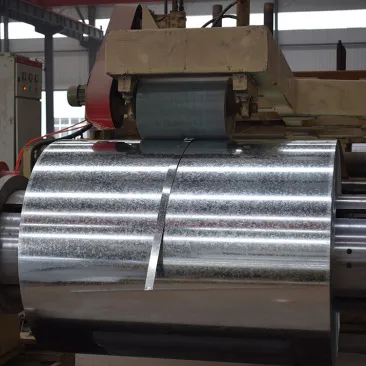

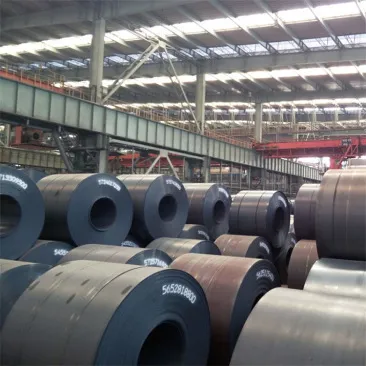

Q235 galvanized coil is a surface galvanized coil with yield strength of 235MPa.Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

The surface of theGalvalume Coil is a unique smooth, flat and gorgeous star, and the basic color is silver white. The special coating structure makes it have excellent corrosion resistance. The normal service life of the Galvalume Coil can reach 25a, and the heat resistance is very good, which can be used in the high temperature environment of 315 ℃; The coating has good adhesion with the paint film, has good processing performance, and can be punched, sheared, welded, etc; The surface conductivity is very good.

Performance and application of material ST37: the material has good performance, that is, through cold rolling, it can obtain cold rolled strip and steel plate with thinner thickness and higher precision, with high straightness, high surface finish, clean and bright surface of cold rolled plate in Taiwan Strait, easy to be coated, various varieties, wide application, high stamping performance, non aging, and low yield point.

1020 belongs to high-quality carbon structural steel. Its strength is slightly higher than 1015 steel. It has good toughness, plasticity and weldability. It is rarely quenched and has no temper brittleness. Parts with high cold deformation plasticity, generally used for bending, calendering, edge bending and hammer arch processing, good welding performance of electric arc welding and contact welding, small thickness during gas welding, strict shape requirements or complex shapes are prone to cracks. Machinability cold drawing or normalizing state is better than annealing state, and is often used to manufacture various mechanical parts with low stress and high toughness requirements.

Due to moderate carbon content and good comprehensive properties, the strength, plasticity, welding and other properties are well matched, which is the most widely used. SS400 steel plate is applicable to bridges, ships and vehicles.SS400 is often rolled into wire rod or round steel, square steel, flat steel, angle steel, I-beam, channel steel, window frame steel and other section steel, medium thick steel plate. It is widely used in buildings and engineering structures. It is used for making steel bars or building workshop frames, high-voltage transmission towers, bridges, vehicles, boilers, containers, ships, etc., and is also widely used as mechanical parts with low performance requirements; C. Grade D steel can also be used as some professional steel.

S235JR is a European standard non alloy structural steel, which is equivalent to the national standard Q235B, that is, carbon structural steel with low carbon content. It is widely used for welding, bolting and riveting structures. It can also be used for building, bridge, ship, vehicle structural parts, manufacturing various tools, cutting tools, molds and measuring tools.

A36 is an American standard carbon structural plate, which is subject to ASTM A36/A36M. This standard is applicable to riveting, bolting and welding structures for bridges and buildings, as well as general purpose structural steel quality carbon steel sections, plates and bars.